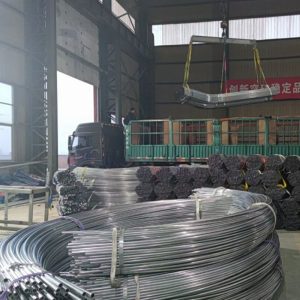

Are you looking for cheap but reliable for galvanized steel pipes & fittings supplier, wholesaler in China? You have came to the right place! DECHO provide in stock hot dip galvanized steel pipes, suitable for usage as water, gas, oil and other industrial usage pipes, purchase with confidence ! [email protected]

What is galvanized steel pipe ?

Galvanized steel pipes are divided into cold-galvanized steel pipes and hot-dip galvanized steel pipes. Cold-galvanized steel pipes have been banned, and the latter can still be temporarily used in China. In the 1960s and 1970s, developed countries in the world began to develop new types of pipes and gradually banned galvanized pipes. China has clearly banned galvanized pipes as water supply pipes since 2000. Cold water pipes in newly built communities have rarely used galvanized pipes, and hot water pipes in some communities are galvanized pipes. Hot-dip galvanized steel pipes are widely used in fire fighting, electric power and highways.

Cold galvanized steel pipe

Cold galvanized steel pipe is electro-galvanized, and the amount of galvanization is very small, only 10-50g/m2, and its corrosion resistance is much worse than that of hot-dip galvanized steel pipe. Most of the regular galvanized steel pipe manufacturers do not use cold galvanized pipes to ensure quality. Only those small factories with small scale and outdated equipment use electro-galvanization, and of course their prices are relatively cheaper. China has eliminated cold-galvanized pipes with outdated technology and is not allowed to use cold-galvanized pipes as water and gas pipes.

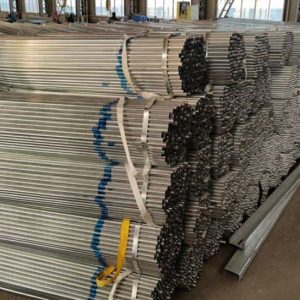

Hot dip galvanized steel pipe

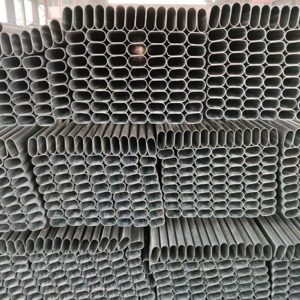

The hot-dip galvanized steel pipe is to make the molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the coating are combined. Hot-dip galvanizing is to first pickle the steel pipe. In order to remove the iron oxide on the surface of the steel pipe, after pickling, it is cleaned in a tank with ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. The matrix of the hot-dip galvanized steel pipe undergoes complex physical and chemical reactions with the molten plating solution to form a corrosion-resistant zinc-iron alloy layer with a compact structure. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix, so it has strong corrosion resistance.

Applications of hot dip galvanized steel pipe

Hot-dip galvanized steel pipes are widely used in construction, machinery, coal mines, chemicals, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery and other manufacturing industries.

Galvanized steel pipes are welded steel pipes with hot-dip galvanized or electro-galvanized layers on the surface. Galvanizing can increase the corrosion resistance of the steel pipe and prolong the service life. Galvanized pipes have a wide range of uses. In addition to line pipes for conveying water, gas, oil and other general low-pressure fluids, they are also used as oil well pipes and oil pipes in the petroleum industry, especially offshore oilfields, as well as oil heaters and condensate for chemical coking equipment, pipes for coolers, coal-distilled wash oil exchangers, pipe piles for trestle bridges, pipes for support frames in mine tunnels, etc.