Product parameters and description

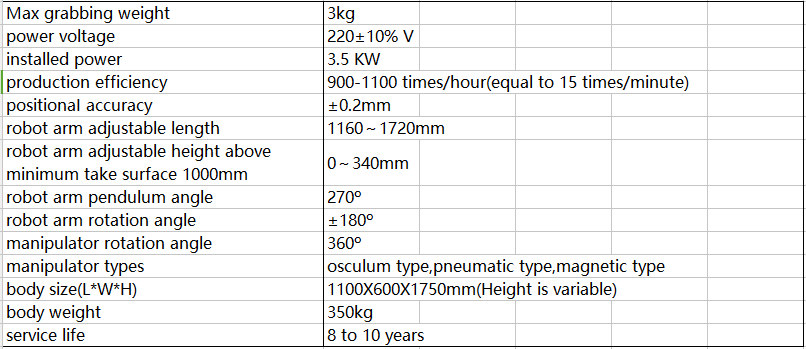

Parameter information:

Product specification:

1. It is suitable for all types of stamping equipment in the market: gear punch, pneumatic punch and hydraulic press, which can be connected at will regardless of tonnage and mesa height, and realize the free combination and connection of equipment;

2. It adopts open programmable technology, supports motion track editing, is easy to operate, flexible to control, intelligently stores product information, has strong interchangeability, and can be used stably for a long time after one setting;

3. All axes adopt high-performance servo system, with reasonable circuit design, optimized layout and stable performance. At the same time, it has the function of power-off position memory to avoid the trouble of origin reset;

4. The load is 3KG. According to the feeding characteristics of the stamping industry, the robot control algorithm independently developed is adopted to realize the linkage control of each axis and automatically generate the optimal motion trajectory. The action is stable and efficient, and the efficiency reaches 15 times/minute;

5. Four-axis/five-axis can be selected, which can realize all-round and multi-angle stamping actions, including turning, punching, side hanging, slanting or stacking, etc., and is suitable for continuous die, single machine multi-die and other die processes;

6. The core components are all famous brands at home and abroad, with stable and reliable quality and performance, the positioning error is controlled within ±0.2mm, the failure rate is less than 1‰, and the service life is 8 ~ 10 years;

7. The products are highly standardized, only the grippers (suction type, pneumatic type, magnetic type, etc.) need to be customized, and the installation is convenient.

Product features:

1. Flexibility: The robot does not need to be fixed, but can move freely according to the requirements of the site to realize multi-site operation

2. Compatibility: The product has the function of moving up and down the shaft, which can realize the free combination of pneumatic punch, gear punch, hydraulic press, drilling machine and tapping machine

3. Stability: Each robot comes with an imported vacuum pump to realize stable, clean and flexible working pressure

4. Fastness: The robot uses a self-developed control card, and the point-to-point programming can be completed in a few minutes

5. Safety: the signals between the robot and the equipment are connected in series to eliminate misoperation. At the same time, double material automatic identification system is adopted

6. Reliability: In 2010, the national invention patent was obtained, and the electrical components were made of Taiwan Province and imported brands. 100,000 tests and inspections were carried out before leaving the factory

7. Economy: Low requirements for customer field equipment and molds, and low transformation cost for introducing automation

8. Standardization: Each robot is a standard machine, which can be universal, freely matched and combined