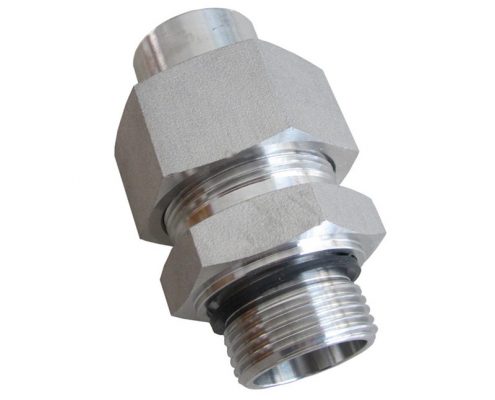

24° Welded fittings/Welded pipe joint

The welded joint and pipeline are connected by welding seam, and the joint body is sealed by compression sealing material. Because the assembly involves welding operation, so the quality of connection is largely affected by welding factors.

The main influencing factors are as follows

1. The mechanical properties of welded joint depend on its chemical composition and microstructure. Therefore, the chemical composition of the joint and the welding performance of the joint are affected by many factors.

welding material

2. Welding rod for manual arc welding, welding wire for automatic submerged arc welding and gas shielded arc welding, etc., become a part of weld metal after melting, which directly affects the chemical composition of weld metal. The flux also affects the chemical composition of the weld.

3. Welding method

The heat source of different welding methods has different temperature and heat concentration. Therefore, the size of the heat affected zone and the thickness of the welded joint are different, so the properties of the joint are different. In addition, different welding methods have different mechanical protection effects. Therefore, the weld metal purity, that is, the content of harmful impurities is different, the performance of the weld will be different.

4. Welding process

Welding, in order to ensure the quality of welding and the selection of various physical quantities (such as welding current, arc voltage, welding speed, line energy, etc.) collectively known as welding process parameters.

Features:

●Secure connection

●High pressure resistance

●Temperature resistance

●Good sealing and repeatability

●Safe and reliable work

Applications:

● Engineering equipment ● Press machines ● Metallurgy ● injection molding ● Compressor ● Oil and gas ● petrochemical ●hydraulics