News Archive

What is the correct installation method for stainless steel flanges?

What is the correct installation method for stainless steel flanges? 1. the stainless steel flange should have sufficient strength and not deform when tightened. The flange sealing surface should be flat and clean, and the oil stains and rust spots should be carefully cleaned up when installing the stainless steel flange. 2.the gasket should have […]

Weldability and its test evaluation for carbon steel material

Carbon steel weldability and its test evaluation 1. Welding: A process in which two objects are combined between atoms to form an inseparable whole by heating or pressing, with or without filling materials. 2. Weldability: refers to the ability of homogeneous or dissimilar materials to be welded to form a complete joint and meet the […]

What are the technical requirements for elbows in engineering projects?

What are the technical requirements for elbows in engineering projects? 1. Since most of the pipe fittings are used for welding, in order to improve the welding quality, the ends are beveled, with a certain angle and a certain side. This requirement is also strict, how thick the side, how much angle and deviation The […]

Features and structure shape of butt welding flange

Butt welding flange is a kind of pipe fittings, which refers to the flange with neck and the transition of round pipe and butt welding with the pipe. Butt welding flanges are not easy to deform, have good sealing, and are widely used. They have corresponding rigidity and elasticity requirements and reasonable butt welding thinning […]

What are the connection methods of wear-resistant ceramic pipes?

Wear-resistant ceramic pipes are widely used in the industrial field, especially in high-wear working environments, such as power plants, cement plants, mines and other enterprises. Wear-resistant ceramic pipes reflect the incomparable advantages of other products. Wear-resistant ceramic pipe connection method 1. Fixed flange connection Fixed flange connection means that the flange is directly welded to […]

What is a bimetal composite wear-resistant pipe?

What is a bimetal composite wear-resistant pipe? The outer wall of the bimetal composite wear-resistant pipe is made of ordinary seamless steel pipe, which is compounded by a high-chromium cast steel lining through a centrifugal forming process. The outer wall of the elbow is made of shrimp elbows, and the inner layer is made of […]

Welding process of bimetal composite pipe

The outer wall of the bimetal wear-resistant composite pipe is made of ordinary seamless steel pipe, which is compounded by a high chromium cast steel lining through a centrifugal forming process. The outer wall of the elbow is made of shrimp elbows, and the inner layer is made of high-chromium cast steel, which not only […]

What is the difference between PTFE lined pipe and rubber lined pipe?

What is the difference between PTFE lined pipe and rubber lined pipe? Tetrafluoro is a polymer of tetrafluoroethylen, short for PTFE. Polytetrafluoroethylene (Poly tetra fluoroethylene, abbreviated as PTFE), is generally called “non-stick coating” or “easy to clean material”. This material is resistant to acids, alkalis, and various organic solvents, and is almost insoluble in all […]

PTFE pipeline is the first choice for industrial sewage lining

Steel-lined PTFE pipe is a kind of green plastic pipe with the most anti-corrosion, wear-resisting, energy saving and environmental protection. Its wide application has accelerated the process of new environmental protection roads in mines to a certain extent. It not only realizes the low-carbon and environmental protection of mine operation, but also saves cost and […]

Process and application of self-propagating ceramic composite pipe

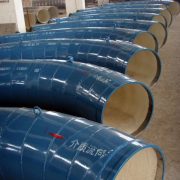

1. The principle of self-propagating ceramic composite pipe: The ceramic composite pipe is manufactured by self-propagating high temperature synthesis + centrifugal casting, that is, the seamless steel pipe is placed in the tube mold of the centrifuge, and the thermite (a mixture of iron oxide powder and aluminum powder) is added to the steel pipe, […]

Process and application of integral calcined ceramic composite pipe

The whole calcined ceramic composite pipe is composed of seamless steel pipe, calcined ceramic pipe and filler Integral calcined ceramic pipeline process Desulfurization ceramic wear-resistant pipes are assembled by firing ceramic pipe fittings as a whole, and pouring the shaped ceramic pipes inside the steel pipe with special fillers. The alumina content of the ceramic […]

Ceramic patch wear-resistant pipe and fittings

Ceramic composite steel pipe: straight pipe, elbow pipe, reducer pipe, tee, pipeline automatic compensator and special-shaped pipe of various specifications between φ50-φ1400 What is a ceramic-lined steel pipe? Ceramic lined steel pipe is a kind of composite pipe that combines ceramic and metal organic. Ceramic steel pipe combines the advantages of high alumina hardness, good […]

The advantages and disadvantages of ceramic chip lined wear-resistant pipes

Features of ceramic chip lined wear-resistant pipes: Paste the ceramic sheet on the steel pipe with high temperature wear-resistant glue to play the role of wear-resistant. The pipe is generally white. Generally used for large diameter pipes Advantages: ceramic patch wear-resistant pipes have good wear resistance (compared to spontaneous combustion) and long service life […]

Why choose ultra-high molecular polyethylene material as the material of the tunnel escape pipe? What are the installation standards?

Tunnel escape pipe The escape pipeline used in the tunnel is made of ultra-high molecular weight polyethylene. The installation of escape pipelines in the tunnel is generally based on prevention and facilitates escape. The tunnel escape pipeline plays a role of secondary defense. The polymer escape pipeline is light in weight, easy to disassemble […]

What is the principle of the escape pipe setting?

What is the principle of the escape pipe setting? 1.Adequate ventilation, tunnel escape ducts and alarm facilities should be set up at the construction site as required. 2.Tunnel construction needs to implement a time-limiting system for operations, and the dangerous projects must be stopped at night. 3.In terms of tunnel escape pipeline support, the construction […]

What do you know about bimetallic pipes?

Introduction of Bimetal Wear-resistant Pipes The bimetallic composite pipe is a new type of wear-resistant pipe developed by our company. The outer layer of the straight pipe is made of ordinary steel pipe, and the high chromium cast iron is formed through the casting process. The inner lining is compounded. The outer wall of the […]

Manufacturing process of dredging sand pumping pipe

The daily application of dredging sand pumping pipes is mainly to discharge silt from rivers, lakes and other places. The accumulation of silt and salt in some river ports will affect the normal navigation of our ships. At this time, we need to The sludge is discharged by the dredging sand pumping pipe, which has […]

Knowledge about wear-resistant pipes

Wear-resistant pipes mainly include wear-resistant elbows, straight pipes, tees, small and small ends, square and round joints, reducing pipes and other structural parts, which are mainly used for pneumatic, pumping slurry and other material transportation pipelines. Because the conveying medium has the characteristics of high hardness, fast flow rate, and large flow rate, it can […]

Three minutes to understand the process of wear-resistant ceramic construction and the precautions of the construction process

General wear-resistant products are mainly used in severely worn industries such as thermal power, steel, smelting, machinery, coal, mining, chemicals, ports and docks; they can be installed in thermal power plants from small units of 50,000 kilowatts to large units of 1 million kilowatts. It can be installed and used in its coal conveying, pulverizing, […]

What is the production process of wear-resistant pipes? What are the advantages?

The wear-resistant pipe is manufactured by the self-propagating high-temperature synthesis-centrifugal method. That is, the seamless steel pipe is placed in the tube mold of the centrifuge, and a mixture of iron oxide powder and aluminum powder is added to the steel tube. This mixture is called the thermite in chemistry. After the centrifuge tube mold […]