News Archive

Nondestructive testing of welded pipe fittings: NDT

Nondestructive testing of welded pipe fittings: NDT Definition of NDT for welded pipe fittings: NDT refers to a testing method for materials or workpieces that does not damage or affect their future performance or use. NDT can find defects in the interior and surface of materials or workpieces, measure the geometric features and dimensions of […]

Tube bending production process

Tube bending production process At present, there are basically two kinds of pipe bending production processes in China: The first type: small-diameter pipeline, the general outer diameter specification is ≤89mm, and cold bending is usually adopted, which is carried out by manual or numerical control pipe bending machine. After bending, annealing heat treatment is needed […]

How are qualified pipe fittings produced?

How are qualified pipe fittings produced? If the finished pipe fittings are viewed from the outside, it is difficult to distinguish between good and bad quality, which is only known during the use process. Engineering quality pays attention to safety first, and once an accident happens, it will cause irreparable losses. So how are high-quality […]

Principle and classification of check valves

Principle and classification of check valves Check valve The function of this type of valve is to allow the medium to flow in one direction only, and to prevent the opposite direction. Usually, this kind of valve works automatically, and the valve flap opens under the pressure of fluid flowing in one direction; When […]

What should we pay attention to when using three screw pump?

What should we pay attention to when using three screw pump? 1. Selection of speed of three screw pump The flow rate of three screw pump has a linear relationship with rotation speed. Compared with the low-speed screw pump, the high-speed screw pump can increase the flow rate and lift, but the power is […]

Horizontal stainless steel storage tank

Characteristics of stainless steel storage tanks: 1. Stainless steel tank has strong corrosion resistance, which is not corroded by residual chlorine in outside air and water. Each spherical tank is subjected to strong pressure test and inspection before leaving the factory, and its service life can reach more than 100 years under normal pressure. 2. […]

What should we pay attention to in the application of wafer butterfly valve?

Wafer butterfly valve is a widely used valve. According to valve materials and driving forms, wafer butterfly valve can adapt to many different industries. Sealing materials for wafer butterfly valves can be roughly divided into two types: soft sealing type and hard sealing type. Soft seal butterfly valve has excellent performance, but it can not […]

Bearings prolong service life-sealing effect

Bearings are the basis for operating machinery, covering fields ranging from mining, motors, machine tools to transportation, power generation, and robotics. Ensuring the longest possible service life is essential to prevent excessive wear and tear; this wear and tear can lead to system failures, often leading to expensive downtime for equipment rebuilds. Engineers can use […]

E-type bearings: toughness and economy

Bearings are used in almost every industry, but sometimes designers need rugged parts that work reliably in the harshest environments. E-type bearings are very suitable for these conditions and can roll smoothly even in the presence of debris, dirt, water, chemicals and high temperatures. Another key benefit is that the rolling elements are tapered roller […]

Three types of harsh environments requiring special bearings

Generally speaking, most bearings, cam followers and other rolling elements are made of AISI52100 material, which is a mixture of degassed low-alloy steel containing a large amount of chromium and carbon. AISI52100 material has high hardness grade and excellent wear resistance and deformability. These characteristics make AISI52100 material an ideal material for ball bearing and […]

What are the design considerations for food-grade bearings?

Bearings are widely used in the food and beverage industry as components in various food processing and packaging machinery. Food-grade bearings must withstand extreme conditions in many applications. Therefore, the life and performance of bearings used in these applications are largely affected by the decisions of designers and engineers. Design considerations that may affect bearing […]

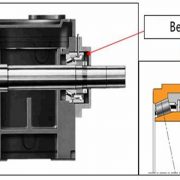

Four type of bearings for machine tool spindles

In the machine tool industry, the spindle is a key component that uses high-speed rotation and pressure forming materials. With the advancement of modern machinery, the requirements for machining equipment are getting higher and higher, more precise and more durable. The bearing is a key component that guides and strengthens the movement of the main […]

Food grade solid lubricating stainless steel bearings

In sensitive food-grade applications and corrosive environments, selecting the right bearing is essential to ensure the best system life and reliability. In these demanding settings, bearings must provide high performance and durability without the need for frequent maintenance or replacement. Over the years, bearing manufacturers have developed a series of solutions designed to resist the […]

Miniature precision bearings in robotics

Thin-section bearings with constant section can significantly save space and reduce the weight of the entire system-an ideal advantage when designing complex and critical applications. Even for large-diameter bearings, the generally square cross-section remains constant. Thin bearings are usually used when space is limited or conventional bearings cannot be used in specific design configurations. They […]

How to adjust the gap between the bearings by adjusting the gasket?

Adjuster gaskets are commonly used in electronic instruments, mold manufacturing, precision machinery, hardware, mechanical parts, stamping parts, and small hardware manufacturing. Repair molds, measure mold gaps, shake, swing, and instability due to mechanical aging. This product can be used to solve machine maintenance problems. How to use adjusting shim to adjust the bearing axial clearance […]

Precautions when installing thrust ball bearings

Precautions when installing thrust ball bearings In the assembly process of thrust ball bearings, planar thrust bearings are mainly used for bearing axial load and are widely used. Although the installation operation of the thrust bearing is simple, the installation operation of the thrust ball bearing is relatively simple, but there are still errors in […]

How to install needle roller bearings?

When the full needle roller bearing is installed, an auxiliary sleeve is generally used. The auxiliary roller cover or the auxiliary roller cover supports the auxiliary roller cover so that the auxiliary roller cover does not fall off, and the auxiliary roller cover uses its own chamfer to lift the auxiliary roller cover. When the […]

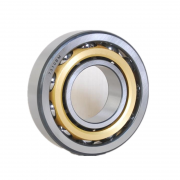

What is the structural difference between deep groove ball bearings and angular contact ball bearings?

Deep groove ball bearings are typical rolling bearings. They are widely used and can withstand radial and bidirectional axial loads. They are suitable for high-speed rotation and require low noise and vibration. Sealed bearings with steel plate dust caps or rubber seals, Pre-filled lubricating grease, outer ring bearing with stop ring or flange, easy to […]

How are angular contact ball bearings maintained?

How are angular contact ball bearings maintained? 1. When the bearing runs for a certain period (or warranty period), remove all the bearings; 2. Use diesel or kerosene to soak and clean the bearing. If there are technical conditions, the sealing cover can be opened for cleaning; 3. Dry the cleaning oil after cleaning, and […]

Introduction to the fixing method of the inner ring of imported bearings

Imported bearings are divided into inner and outer rings. I think everyone knows this. So what is the fixing method of the inner and outer rings of the imported bearing? First, let’s introduce the fixing method of the inner ring of the imported bearing. 1. Fixed shoulder The inner ring of the bearing is axially […]