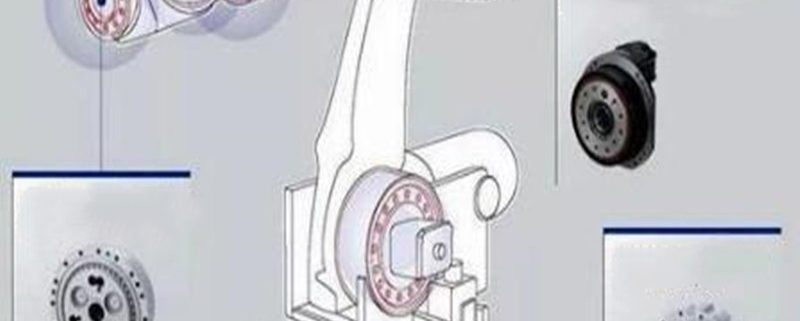

Miniature precision bearings in robotics

Thin-section bearings with constant section can significantly save space and reduce the weight of the entire system-an ideal advantage when designing complex and critical applications. Even for large-diameter bearings, the generally square cross-section remains constant. Thin bearings are usually used when space is limited or conventional bearings cannot be used in specific design configurations. They can be used in many applications and have a variety of contact angle designs, including radial contact, angular contact and four-point contact.

Meanwhile, miniature ball bearings are small bearings that use balls as rolling elements. Miniature precision bearings can be widely used in precision robotics applications, helping to reduce friction between parts that need to move independently, while effectively saving space in compact applications, such as medical, instrumentation, and semiconductor equipment. These balls are available in various sizes to meet the needs of specific projects.

Due to its unique design advantages, thin bearings and miniature ball bearings are often used in robotics and other critical applications.

Common thin section bearing applications

Different from most radial ball bearings, regardless of the aperture size, the cross-sectional diameter of the thin-section bearing remains the same, thereby reducing the system cost and simplifying the overall design. Its compact, lightweight design makes it ideal for a variety of robotic applications, including manual assistance, pick and place, semiconductor and medical.

High-tech applications usually require customized bearings with special materials, surface coatings or lubricants to meet special machine requirements. Thin section bearings can effectively meet these types of application requirements, including very low or uniform torque, high positioning accuracy, corrosion resistance, and compatibility with very clean environments. The application of camera equipment also utilizes thin-section bearings because their light weight helps to ensure the rigidity and stability of the system.

The challenge of miniaturization

Although miniature bearings are extremely versatile, they may still bring various maintenance and flexibility challenges. The smaller the bearing, the more important it is to keep an eye on these issues. First, regular maintenance is required to maintain longevity and smooth operation. For this reason, regular lubrication or lubrication of built-in bearings is essential.

Similarly, for small bearings, size and capacity options may be relatively limited, which is a problem for high-load projects. If your application requires a certain size or width, make sure to pair with a company that can provide appropriate bearings or customized services.

In some cases, smaller bearing sizes may also preclude design flexibility. Whether you are looking for corrosion-resistant coatings, ceramic balls or interchangeable components, you can pair with suppliers who can provide the options you need.

Decho is a professional supplier of bearings , widely used in robotics. If you need any , pls contact us by email [email protected]