How are seamless steel pipes produced?

How are seamless steel pipes produced?

The production process of seamless steel pipes is mainly divided into two types: cold-drawn and hot-rolled. The production process of cold-rolled seamless steel pipes is more complicated than that of hot-rolled steel pipes. The pipe billet must firstly be under three-roll continuous rolling, and then sizing test after extrusion. If the surface does not respond to cracks, the pipe will be cut by a cutting machine about one meter length. Then entering into annealing process, the annealing should be pickled with acidic liquid. When pickling, pay attention to whether there is a lot of blistering on the surface. If there is a lot of blistering, it means that the quality of the steel pipe does not meet the corresponding standards.

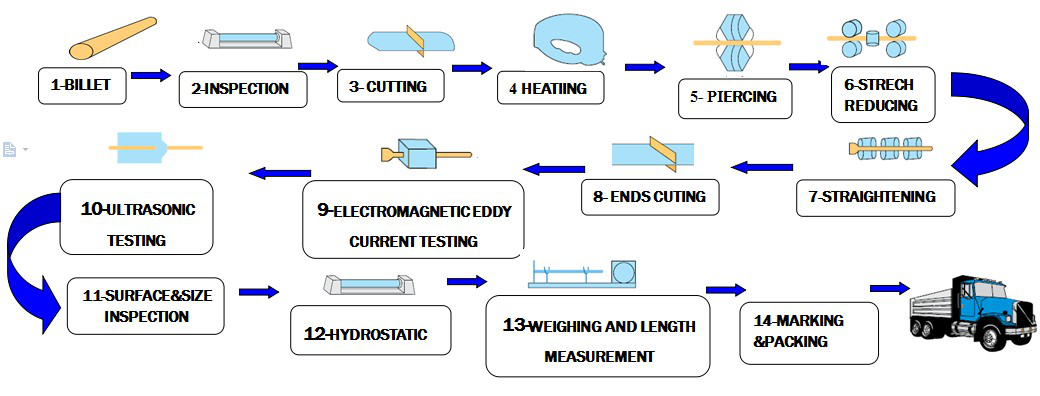

Main production processes of hot-rolled seamless steel pipes (*main inspection processes):

Tube billet preparation and inspection*→tube billet heating→perforation→tube rolling→steel pipe reheating→fixed (reduced) diameter→heat treatment*→finished tube straightening→finishing→inspection* (non-destructive, physical and chemical, bench inspection) → warehousing

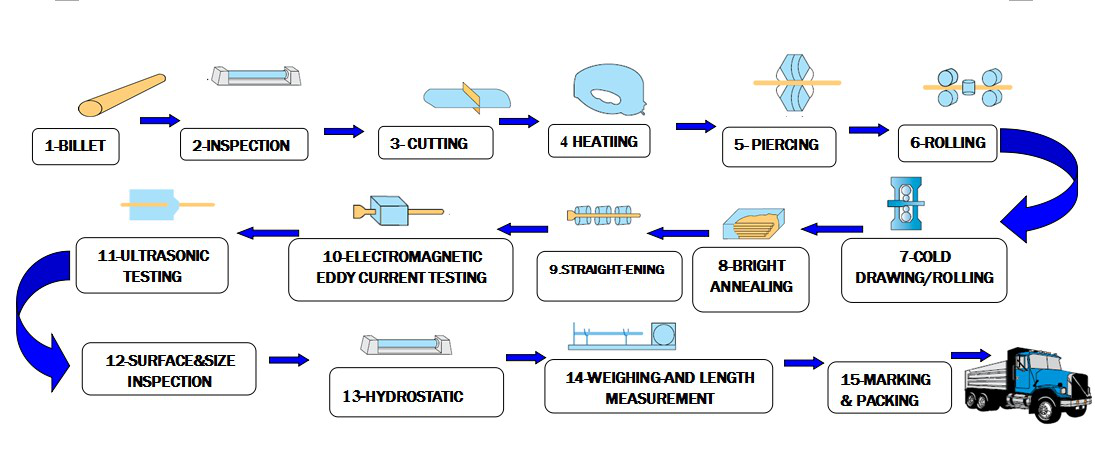

The main production process of cold rolled (drawn) seamless steel pipe:

Billets preparation → pickling and lubrication → cold rolling (drawing) → heat treatment → straightening → finishing → inspection

How to distinguish hot rolled pipes and cold rolled pipes ?

In length, cold-rolled seamless steel pipes are shorter than hot-rolled seamless steel pipes. The wall thickness of cold-rolled seamless steel pipes is generally thinner than that of hot-rolled seamless steel pipes, but the hot-rolled seamless steel pipes look brighter on the surface without much rough caliber and there are not too many burrs. The delivery conditions of hot-rolled seamless steel pipes is generally delivered after hot rolled or heat treatment. After the quality inspection, the hot-rolled seamless steel pipe must be strictly hand-selected by the inspectors. After the quality inspection, the surface should be oiled, and then followed by multiple experiments. After the hot-rolling treatment, the piercing experiment should be carried out. If the perforation is too large, it must be straightened. After straightening, it is transferred by the conveyor to the flaw detector for flaw detection experiment, and finally the label is affixed, the specification is arranged, and then it is placed in the warehouse.

Decho is able to supply various seamless steel pipes with different specifications and for different usages, if you are interested in our seamless steel pipes, please contact [email protected]